Optics

Application

Specular Reflectors combine and integrate in one solid optical element attributes and technical characteristics necessary

to perform simultaneously the following functions:

(a) cooling duct for both lamp(s) and laser rod(s);

(b) filtering-absorbing undesired UV radiation, thus protecting the rod from long term solarization;

(c) attenuating “lateral depumping” effects i.e. energy losses caused by the rod’s side emission, by absorbing it and

preventing its back-reflection

(d) reflecting of lamp emitted light energy for pumping of laser rod.

Technical Description

A Reflector element is machined out of a block or a rod of carefully selected high optical quality Glass or Quartz Glass material, un-doped or doped with the appropriate rare earth or metal ions, depending on the filtering results we are looking after and on the state of the available doping/filtering optical materials technology.

From its skilled alignment during the deep-boring to produce the holes that shall house the rods and lamps, till its polishing stage, the highest parallelism and perpendicularity tolerances must be observed in order to achieve an efficiently operating element. The polished exterior cylin¬drical surface is then coated with HR silver and/or other metallic coatings, to form the high efficiency Specular Reflector. We are measuring and controlling the transmission characteristics of the produced Reflector elements using Zeiss spectrophotometer. We can use chemical and electrochemical (Galvanic) coatings with Silver/Nickel and Copper/Nickel or other layers to shape the Reflector surface.

Typical configurations

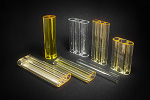

Various sizes and shapes of multifunctional Reflector structures to be used in Solid State Laser Heads are usually available within short notice in a tube-like form of circular and elliptical profile. Typically they can house one or more lamps or rods. We can deliver Reflectors both unpolished, polished/uncoated and polished/coated with Metallic coating (usually silver).

Capabilities

LT-PYRKAL undertakes applied research, design and development of Reflector Flowtube elements to customer’s requirements. Our optical design and manufacturing experience include working with various hard crystals and all kinds of soft, medium and hard Glasses and Ceramics currently known and available in the Optics and Laser Optics market.

We have specific capabilities for the design and for the execution of all accurate cutting, deep-boring, grinding and polishing operations necessary to build various Reflector Flowtube shapes and configurations. Most probably, we can be of assistance to your Laser Pump Head concepts, drawings and specifications. Upon request, we can use Europium, Samarium, Cerium or other doped materials for intra-cavity filtering.